Expanding Your Business Potential with Laser Equipment

The Impact of Laser Technology on Metal Fabricators

In today's fast-paced industrial environment, metal fabricators need to stay ahead of the competition by embracing cutting-edge technology. One such technology that has revolutionized the metal fabrication industry is laser equipment. As a metal fabricator, incorporating laser machinery into your production process can significantly enhance your business capabilities and open new opportunities for growth.

Precision and Versatility

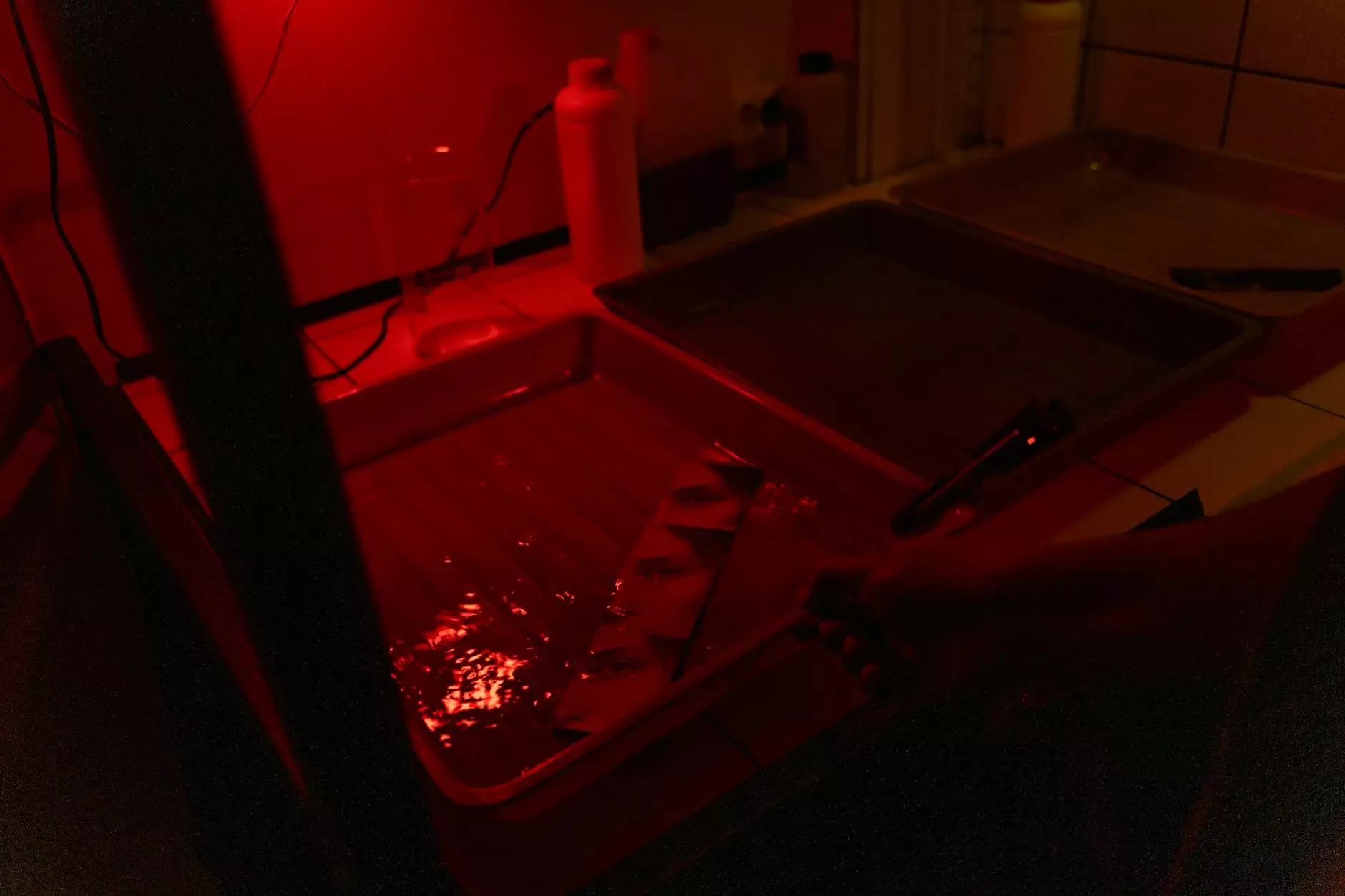

Laser equipment offers exceptional precision, allowing you to achieve high-quality cuts, welds, and engravings with utmost accuracy. The pinpoint accuracy of lasers ensures minimal material wastage, which in turn translates to cost savings for your business. With laser technology, you can tackle intricate designs and complex geometries that would be challenging or impossible otherwise.

Furthermore, laser machines offer great versatility. They can work with a wide range of materials, including various types of metals, plastics, and even organic materials. This flexibility allows metal fabricators to diversify their product offerings, attracting a broader customer base and finding new market opportunities.

Increased Productivity and Efficiency

By integrating laser equipment into your metal fabrication process, you can significantly increase productivity and efficiency. Laser cutting and welding processes are typically faster than traditional methods. The automated nature of laser machinery ensures consistent and repeatable results, minimizing human errors and rework, and reducing overall production time.

Moreover, laser machines often feature advanced software and control systems that enable precise monitoring and optimization of the manufacturing process. Real-time data analysis and automatic adjustments allow you to fine-tune production parameters, resulting in improved efficiency, reduced cycle times, and higher output levels.

Cost-Effective and Environmentally Friendly

While investing in laser equipment may require an initial upfront cost, it brings long-term cost benefits. Laser technology is known for its energy efficiency, consuming significantly less power compared to traditional machining methods. This translates to lower energy bills, contributing to overall cost savings in the long run.

Additionally, laser cutting and welding processes generate less waste and produce minimal fumes compared to conventional methods. Laser equipment operates with high precision, reducing the need for additional finishing work, and minimizing material waste. This eco-friendly approach not only aligns with sustainable business practices but also helps you save money on wastage and post-processing.

Competitive Advantage with DP Laser's Cutting-Edge Solutions

When it comes to choosing the right laser equipment for your metal fabrication needs, DP Laser has proven expertise and a comprehensive range of solutions.

Diverse Range of Laser Machinery

At DP Laser, we offer a diverse range of laser equipment tailored to the specific requirements of metal fabricators. Our selection includes laser cutting machines, laser welding systems, and laser engraving machines, among others. Whether you are in the automotive, aerospace, or jewelry industry, we have the perfect laser solution to help you excel in your field.

Advanced Features and Technology

Our laser equipment incorporates the latest technological advancements, ensuring optimal performance and reliability. With features like advanced control systems, intelligent software, and automatic calibration, our machines empower you to achieve outstanding precision and efficiency in your metal fabrication operations.

Unparalleled Support and Service

At DP Laser, we prioritize customer satisfaction and provide unparalleled support and service. Our team of experienced technicians is always ready to assist you with installation, training, and ongoing maintenance. We are committed to ensuring that your transition to laser technology is smooth and seamless, enabling you to maximize the benefits of our equipment and stay ahead in the competitive marketplace.

Conclusion

Incorporating laser equipment into your metal fabrication business can bring numerous advantages, from enhanced precision and versatility to increased productivity, cost savings, and a competitive edge. By partnering with DP Laser, a trusted provider of cutting-edge laser solutions, you can unlock the full potential of laser technology and take your business to new heights. Embrace the power of lasers and secure a prosperous future for your metal fabrication enterprise.